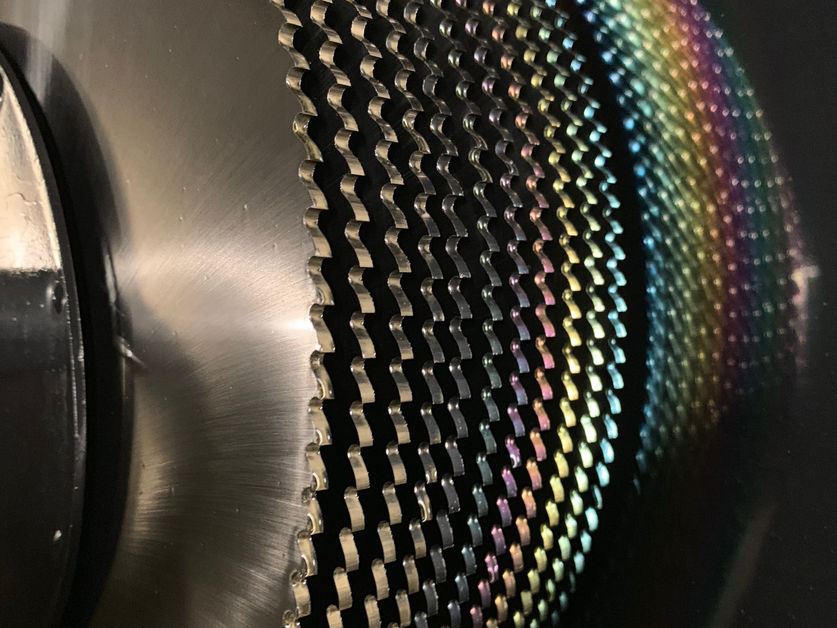

HSS Cold Saw Blades

HSS cold saw blades are usually made from either M2 (DMo5) tool steel or M35 (EMo5Co5) tool steel, alloyed with additional cobalt. HSS cold saw blades are heat treated and hardened to 64/65 HRc. This high rockwell hardness gives the cutting edges of the teeth a high resistance to heat and wear. Our blades are press quenched after hardening to prevent them from being warped. The term high speed steel (HSS) doesn't necessarily mean what it implies. These blades are usually run at surface speeds lower than 350 SFM. HSS cold saw blades may be used for cutting many different shapes and types of metal including: tubes, extrusions, structural sections, billets, bars, ingots, castings, forgings etc. Contact us to learn more.

Download Catalogs

Tooth Forms

Applications

HSS cold saw blades are used to cut many common materials.

Precision Machined Components